The Barmag GP series for paint applications

A selection of replaceable pressure sensor blocks to enable different installations

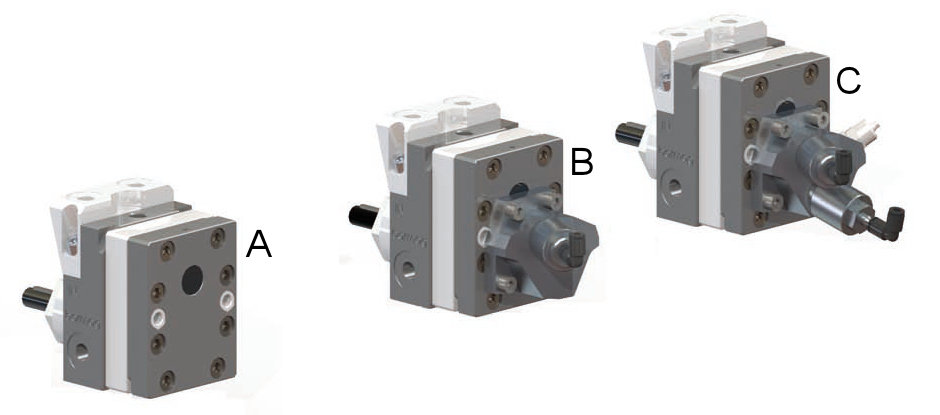

GP paint metering pump. A Non-flushable. B With flushing valve for tooth flank flushing. C With flushing valve for tooth flank and bearing flushing

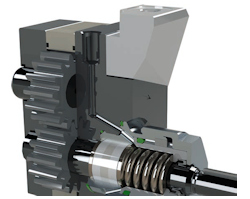

GP paint metering pump with spring-loaded stuffing box for low-maintenance shaft sealing.

The GP series

Oerlikon Barmag has been manufacturing precision gear metering pumps since the company was founded in 1922. Since 1985, Oerlikon Barmag has more than 50,000 paint metering and surface coating pumps in operation throughout the world.

They are used to efficiently apply paints in various industrial applications, such as in automobile manufacture, in the aerospace industry and in the renewable energy sector.

In many of these manufacturing processes applying paint to the finished product is often a challenge. Paint systems must be applied flawlessly – both in terms of look and feel – to comply with the ever-higher durability demands for

the end product. Oerlikon Barmag’s precision gear metering pumps enable this to be achieved with a high degree of reliability. The finest tolerances and manufacturing quality determine these pumps’ metering accuracy, which in turn,

determines the quality of the coating on the end product.

The pumps excel in terms of their flow-enhancing design and absence of dead spots. This is essential to achieve short flushing times and low consumption of flushing agents, thereby maximising productivity while minimising the environmental impact.

The GP range of pumps has been developed for use with both solvent-based and water-based paints. The pumps are manufactured in non-corrosive and acid-resistant steel. For metering highly abrasive paints, a DLC coating provides the pumps with extended durability. Ceramic components can also be used to increase pump life. Another feature is the flushing block with connections for solvent feed and air pressure. Rapid colour changes are possible with the tooth flank and bearing flushing features of these pumps. These weight-optimized metering pumps are available in capacities between 1.2 cc/rev and 9 cc/rev. External dimensions are identical, meaning they can be swapped out with no changes to pipework.

Highlights

• Flexibility with various pressure sensor blocks

• Extended service life with

-DLC wear-protection layer and

-Optimized orientation of the plate package

-Utilization of ceramic components (optional)

• Lower weight by

-Compact design

-Utilization of light metal sealing components

• Seal system

-Spring-loaded stuffing box, with optional buffer fluid

-O-ring sealed plate package

Accessories

• ATEX certificate

•Pressure sensors for monitoring inlet and outlet pressures for even metering

• Flushing block for tooth flank flushing and tooth flank and bearing flushing

The information supplied in this brochure is for guidance only. We reserve the right to modify it at any time